MECAMAX, A NEW DIMENSION IN MACHINING

Mecamax steels have been developed for applications involving machining processes in order to increase their productivity.

Advantages

- Faster cutting speed.

- Leas wear.

- More consistency.

- Same properties.

RESISTANCE

Corrosion resistance and machinability

Easily machining stainless steel has up to now meant losing corrosion resistance due to the use of elements such as sulphur or selenium to improving the cutting ability. The situation has changed with the arrival of the MECAMAX technology.

MECAMAX is used to improve the machining response of each of the steels, without losing the other properties particularly their corrosion resistance and their mechanical properties.

A rigorous control of the sulphur content, together with obtaining inclusions to facilitate the machining process, allow a better response to the machining, while guaranteeing the base steel and compliance of the applicable standards, both from the point of view of the application and from hygiene or environmental aspects.

This improvement solely implies acting on the inclusions and not on the base composition of the steel. That also maintains the chemical analysis specified for the stainless steel in question. Therefore, it maintains the weldability, corrosion resistance, cold and hot formability, along with the mechanical characteristics of the base steel.

MACHINING TESTS

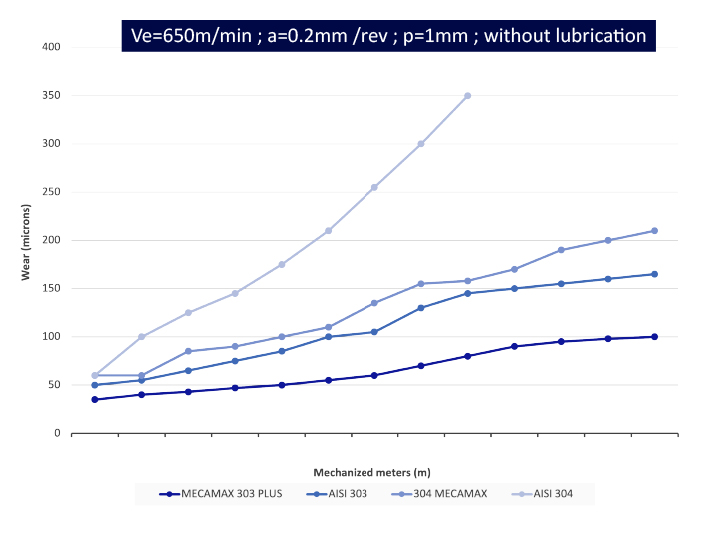

· Tool wear

Tool wear tests conducted using materials manufactured using Mecamax technology show the significant improvement achieved. When standard grade 304 stainless steel is compared to Mecamax grade 304 steel, the wear is much lower and even close to the levels for high surphur steel.

The same test conducted with grade 303 steel confirms the effectiveness of this steel family in machining processes.

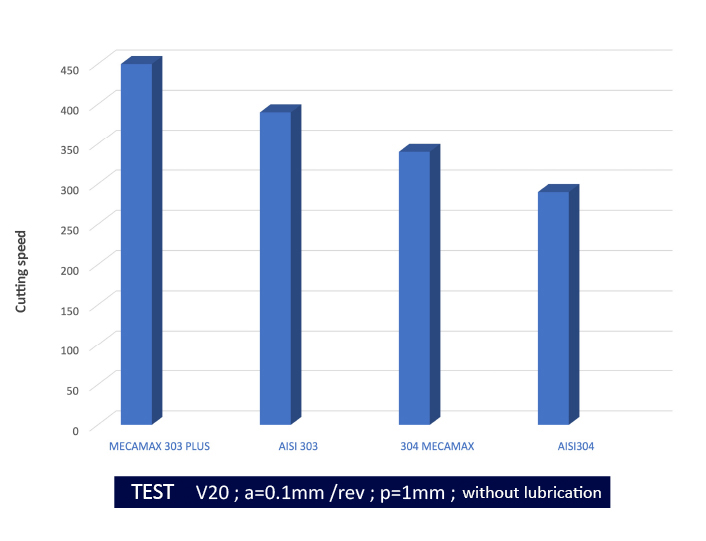

· Cutting speed

Machining cutting speed tests are conducted by measuring the applicable maximum cutting speed for a set tool life, 20 minutes in this case.

In every test, the application of Mecamax technology allows much higher cutting speeds to be achieved than those for standard steels.

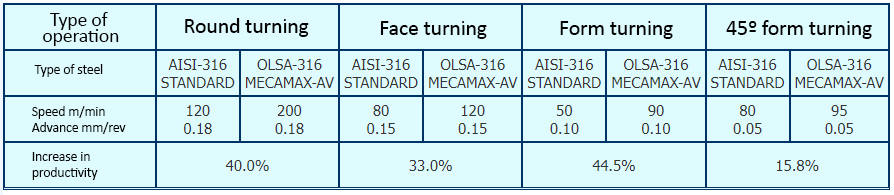

INDUSTRIAL MACHINING

An industrial test is the best way of assessing the machining performance of a steel. Therefore, Olarra tested the MECAMAX-AV grade 316 steel with manufactured parts, as can be seen from the photograph.

The following operations were carried out to manufacture those parts: cylinder-rolling, facing, standard turning and shape turning at 45º, machining a Ø 32mm using ISO P40 hard metal tools in an automatic lathe.

The results are set out on the following table. It should be noted the tool wear in those tests was 65% lower when machining MECAMAX-AV steel than when using standard steel. Another point of interest that must be stressed is that the total machining time per part is 29% shorter when using MECAMAX-AV steel.